MONDEO produces stainless steel valves, manifolds and accessories. These products supply top levels of hydraulic efficiency in all liquid movement systems, no matter whether domestic, for food, plumbing or industrial. MONDEO production technology guarantees reliability and high standards of efficiency and quality.

Products

Check valves

Check valves, also called non-return valves, allow fluids to flow in a single direction. You can find them at the outlet of the hydraulic system, where fluid return has to be avoided, no matter whether domestic hot water, air, or industrial, discharge and drainage liquids. Check valves work automatically and according to the difference in pressure between the section upstream and downstream of the stem.

Available types of check valve:

The valves can be spring loaded, disc, ball, wafer disc, double disc wafer, swing, wafer swing and foot flanged according to the closing system. They can be made of AISI 304 and AISI 316 steel, brass, cast iron and plastic. The stainless steel check valves produced by Mondeo – Idria, Small, Glovalve and Floy – guarantee contained load loss and better system efficiency thanks to their special shape.

Check valve applications:

Check valves cover a wide range of applications: working pressures from 6 bar to 350 bar and temperatures from -25 to +250 °C. Their versatility makes them perfect for various applications. They are suitable for both industrial and domestic use, in water and industrial liquid treatment plants, in pump groups for civil and industrial water, for compressed air, liquid waste and sewers.

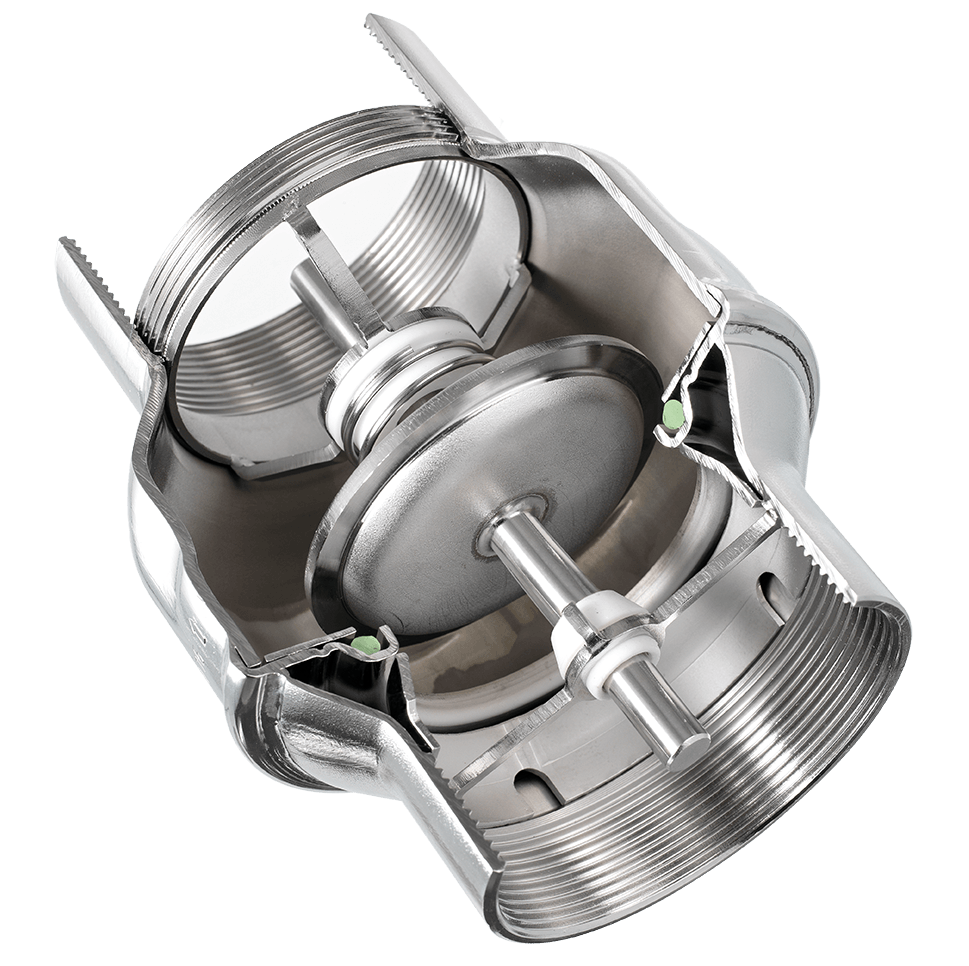

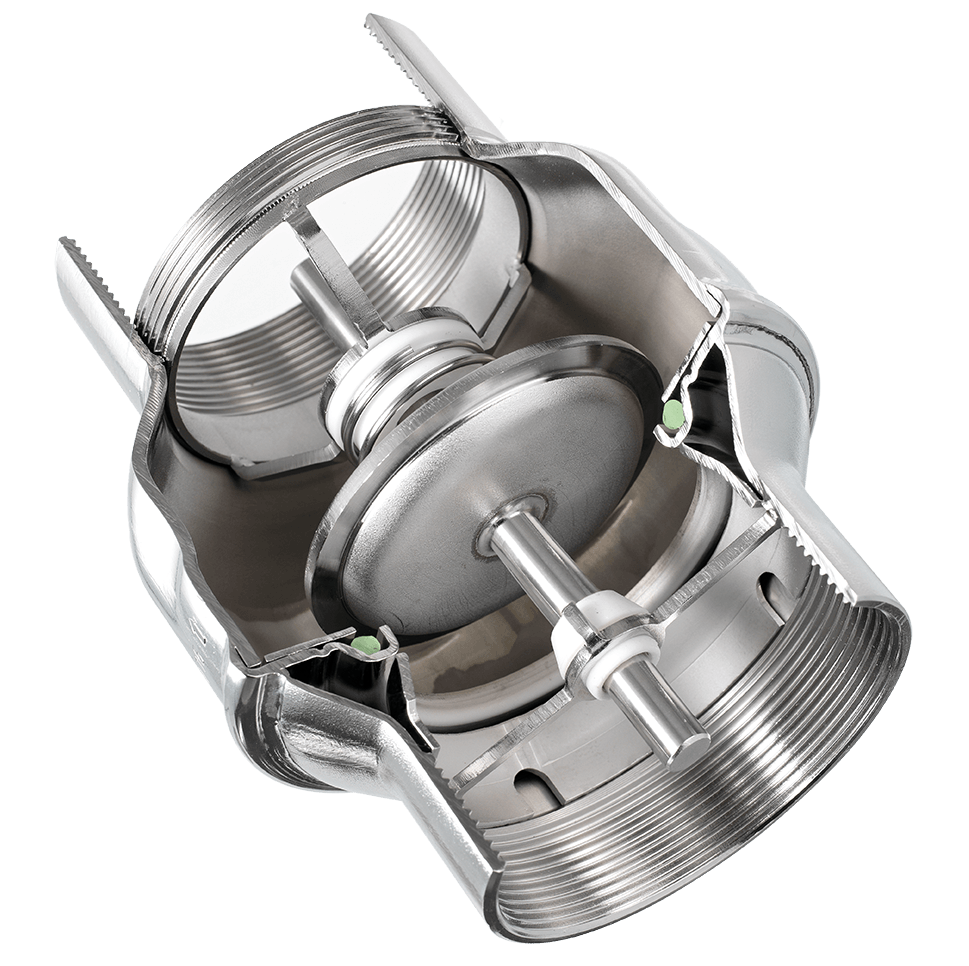

Idrja – Check valves fabricated from pressed stainless steel

Technical features:

- Manufacturing process pressed stainless steel

- Body valve and metallic parts stainless steel Aisi 304 or Aisi 316

- Seal ring NBR, FPM, PTFE o FEP

- Threaded ends UNI ISO 228/1 female

- Welded joints without any additional material

- Opening pressure Min. 0,025 bar Max. 0,035 bar

- Hydraulic test on the seal ring compressed air at 0,2 bar on each valve

- Nominal working pressure 16 Bar

Working temperature:

- -25°C – +90°C (with NBR seal)

- -20°C – +110°C (with EPDM seal)

- -20°C – +150°C (with FPM seal)

- –20°C – +200°C (with PTFE o FEP seal)

Size 1″ – 1″ 1/4 – 1″ 1/2 – 2″ – 2″ 1/2 – 3″ – 4″

Idrja AC – Check valves for heavy duty use and compressed air

Technical features:

- Compressed air systems

- Doubled guided reinforced flow control disc

- Suited for heavy-duty use

- Threaded ends female UNI ISO 228/1

- Nominal working pressure 16 bar

- Opening pressure Min. 0,025 bar Max. 0,035 bar

- Working temperature with FPM seal -20°C – +150°C

Small – Small diameter check valves (from 1/4” to 1/2”)

Technical features:

- Manufacturing process machined/pressed stainless steel

- Body valve and metallic parts stainless steel Aisi 304 or Aisi 316

- Seal ring NBR, EPDM, FPM o PTFE

- Threaded ends UNI ISO 228/1 female

- Welded joints tig method without any additional material

- Opening pressure Min. 0,025 bar Max. 0,035 bar

- Hydraulic test on the seal ring compressed air at 0,2 bar on each valve

- Nominal working pressure 16 bar

Working temperature

- -25°C – +90°C (with NBR seal)

- -20°C – +110°C (with EPDM seal))

- -20°C – +150°C (with FPM seal)

- -20°C – +200°C (with PTFE seal)

Size 1/4″ – 3/8″ – 1/2″

A Check valve 1/2”

B Check valve 1/4 and 3/8””

Small AC – Small diameter check valves for heavy duty use and compressed air

Technical features:

- Compressed air systems

- Doubled guided reinforced flow control disc

- Suited for heavy-duty use

- Threaded ends female UNI ISO 228/1

- Nominal working pressure 16 bar

- Opening pressure Min. 0,025 bar Max. 0,035 bar

- Working temperature with FPM seal -20°C – +150°C

Cromax AP – High pressure single disk check valves

Technical features:

- Body valve stainless steel Aisi 316

- Disk stainless steel Aisi 316

- Spring stainless steel Aisi 316

- Threaded ends EN 10226-1 female gas

- Sealing system metal to metal

- Max. Working pressure 63 bar

Working temperature

Size 1/4″ – 3/8″ – 1/2″ – 3/4″ – 1” – 1” 1/4 – 1” 1/2 – 2” – 2”1/2 – 3” – 4”

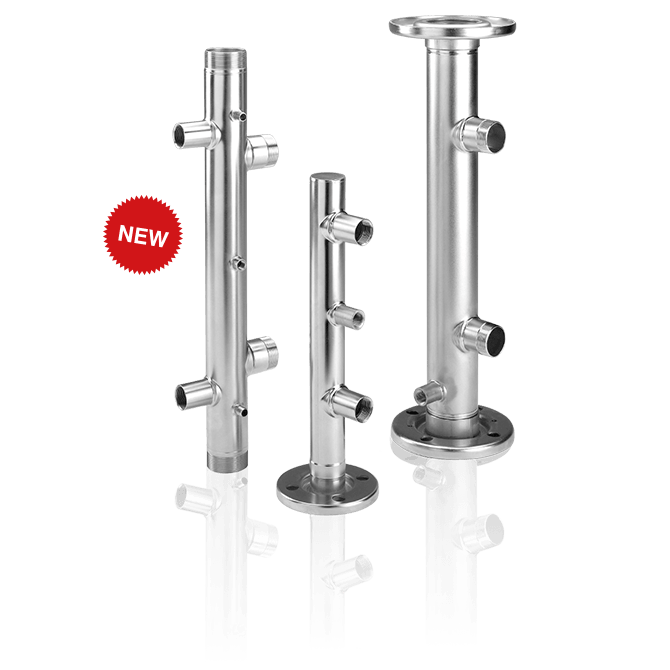

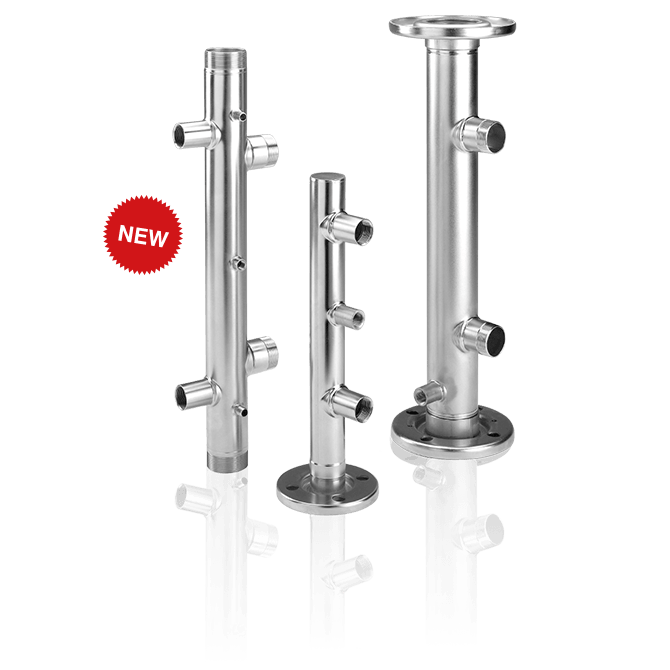

Manifolds

Manifolds are generally used to connect different segments of a hydraulic system, or to connect two pump units to obtain a higher flow rate. Mondeo manifolds are made of stainless steel. Thanks to their slimness, which increases the inner flow surface of the fluid, and TIG-welded threaded parts, load losses are reduced to a minimum. In addition to their optimal hydraulic efficiency, another strong point of our manifolds is that both their size and their configuration can be personalized.

Hydraulic manifold applications:

These manifolds are suitable for transferring domestic hot water, in heating systems, for drinking water. In addition to the plumbing and drainage sector, they are used in water purification systems or for treating industrial water. They can be used in buildings for floor heating, for connecting water meters and for battery connecting water meters. To make pump group assembly easier, kits with the support bases for the pumps, the manifolds, the support for the electric panel, the valves and all the necessary accessories are available.

New dual – Manifolds for water booster units

Technical features:

- Manufacturing process pipes cold buckling

- Material stainless steel Aisi 304 (Aisi 316 only on request)

- Welded joints made with TIG method without any additional material

- Surface treatment: Degreasing, pickling and electro polishing

- Threaded ends UNI ISO 228/1 gas cylindrical

- Nominal working pressure 16 bar

- – Kit base ZNT – Galvanized steel bases for 2 pumps

– Kit base new – Bases for 2 pumps water booster unites

– Kit base ZNT VER – Galvanized steel multipurpose base for 2 vertical pumps

– New dual WM – Manifolds for water meters

– Modual -Modular manifolds

– New heat BL – Double sided simple manifolds for heating plants

– New dual HS – Multifunctioning hydraulic separator

Pneumatic valves

Motorized valves are ball and butterfly interception valves, with an apparatus that permits remote closing and opening by way of an electric or pneumatic actuator. The pneumatic actuator transmits movement to the valve using compressed air as the movement fluid. Pneumatic actuators can be double or single effect: in the first case it is the air that opens and closes, while in the other case closing is controlled by a spring.

Pneumatic actuator – Pneumatic valve

Operating conditions:

- Pneumatic valve: H5015: 2 pcs full bore ball valve

- H5025: 3 pcs full bore ball valve

- H5114: Wafer type butterfly valve

- Operating media dry or lubricated air, non-corrosive gases or oil

- Air supply pressure 5 bar (2-8 bar)

- Highest pressure maximum input pressure is 8 bar

- Operating temperature Standard: -20 °C +80 °C

- Low temperature: -35 °C +80 °C

- Hight temperature: -15 °C +150 °C

- Travel adjustment Have adjustment range of ±5° for the rotation at 90°

- Lubrication Under normal operating condition, lubricant not needed

- Applications Either indoor or outdoor

- – 2 pieces ball valve

- – 3 pieces ball valve

- – Butterfly valve

- – SS butterfly valve

Hydraulic filters

Steel hydraulic filters for water and other liquids

Filters eliminate the impurities in the liquids that circulate inside a hydraulic system. They can be installed at the inlet point and inside the system to prevent the solid particles in suspension from damaging pumps, sensors and measuring instruments. They are available in stainless steel, brass and galvanised steel with diameters from ¼’ to 4’ and larger.

They can be used in both domestic and industrial environments where the maximum pressure reaches 16 bar and the maximum temperature 200 °C.

Idrja-small – Suction screen

Technical features:

- Net-filter stainless steel Aisi 304 or Aisi 316

- Coupling stainless steel Aisi 304 or Aisi 316

- Threaded end gas male UNI ISO 228/1

- Filtration: U.S. mesh: 18 (from 3/8” to 2”), U.S. mesh: 10 (from 2” 1/2 to 4”)

- Size: 3/8” – 1/2” – 3/4” – 1” – 1” 1/4 – 1” 1/2 – 2” – 2” 1/2 – 3” – 4”

Amita – Suction screens with pa coupling

Technical features:

- Net-filter stainless steel Aisi 304

- Coupling PA (nylon)

- Threaded end gas male UNI ISO 228/1

- Filtration: U.S. mesh 18

- Size: 3/8” – 1/2” – 3/4” – 1” – 1” 1/4 – 1” 1/2 – 2” – 2” 1/2 – 3” – 4”

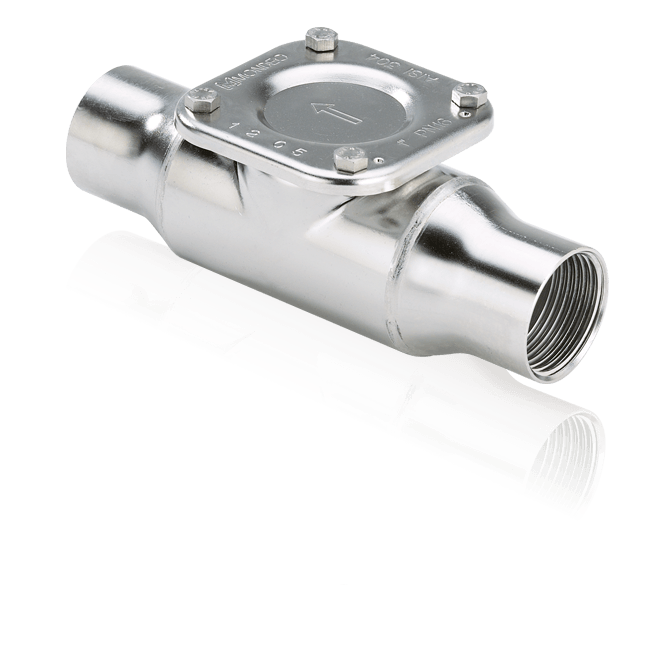

Linia – IN-Line filters

Technical features:

- Manufacturing process pressed stainless steel

- Body valve and metallic parts in stainless steel Aisi 304

- Surface treatment degreasing, pickling and electropolishing

- Seal ring FPM

- Threaded ends UNI ISO 228/1 gas female

- Welded joints made with TIG method without any additional material

- Hydraulic test on welded joints compressed air at 2 bar on each filter

- Nominal working pressure 16 bar

- Working temperature -10°C – +150°C (with FPM seal)

- Filtration: 500 μ (from 1/2” to 1”) 800 μ (from 1” 1/4 to 2”)

- Size: 1/2 – 3/4” – 1” – 1” 1/4 – 1” 1/2 – 2”